What Is A Tension Fabric Building & What to Consider to Buy

Whether it is used as a storage facility, a sports stadium, or for hosting large events, tension fabric building offers a wide range of solutions. Its unique structure and flexibility attract a large number of businesses and organizations with specific needs, and more and more people are considering buying one.

So what is a tension membrane building? What are the key factors you need to consider before buying one? Firstly, you need to have a clear understanding of it and understand its application scenarios and core benefits.

This article will help you clarify the concept and explore the various factors you need to weigh up when making a purchase.

What Is A Tension Fabric Building?

The core structure of the tension fabric building is supported by a metal frame (e.g., steel tubing or aluminum alloy profiles), and a special membrane (e.g., PVC or PTFE-coated fabric) is tensioned over the frame to create a solid shelter.

The advantages of tension fabric structures over traditional buildings are significant. Traditional buildings rely on brick or reinforced concrete, which are costly and immovable.

In contrast, tension fabric buildings use modular prefabricated components for highly efficient on-site assembly, saving more than 50% of construction time; their lightweight structure reduces foundation requirements, further reducing costs.

At the same time, the membrane material is corrosion-resistant and self-cleaning, and the metal frame (especially aluminum alloy) has excellent rust and corrosion resistance in humid environments, so the maintenance cost is much lower than the regular repair needs of traditional buildings.

Additionally, tension fabric structures are designed with large-span capabilities and a column-free interior, providing expansive, unobstructed space.

Where Are These Tensile Fabric Structures Used?

Tension fabric building can be suitable for temporary or short to medium-term use due to its structural and design advantages. Examples include outdoor exhibitions, music festivals, and event venues.

It is worth mentioning that, especially in disaster relief and emergency scenarios, due to the rapid deployment, fabric buildings can quickly provide medical tents, storage space for materials, and can be reused.

As well, construction sites often use it as temporary shed or equipment storage. It avoids the problem of wasting building materials in traditional temporary buildings.

Tension fabric building also excels in semi-permanent applications. Agricultural greenhouses or livestock farms take advantage of their light and ventilation to optimize the environment for growing crops, with ample headroom and customizable transparent coverings. Most metal frames have a long lifespan, with aluminum alloys having a 20-year lifespan when well-maintained.

Industrial warehouses and logistics centers rely on their large spans and column-free spaces to improve the efficiency of goods storage, and can be flexibly expanded later by adding or removing modules.

If you're considering this type of building, here's an analysis of the key factors to consider when making your selection.

What to Consider Before Buying a Tension Fabric Building?

After clarifying the applicable scenarios of tension fabric building, you should buy it according to your usage. Therefore, the following core elements need to be evaluated: material weather ability and structural life, compliant structural report to verify safety, and so on.

Below is a breakdown of each of these elements to help you avoid potential risks.

High-quality Material for Weather Resistance and Long-term Use

The material of the metal frame directly determines the resistance and service life of the tension fabric building. Take tension fabric structures for high-strength aluminum alloy as an example.

Aluminum alloy is treated with a special process (e.g. anodic oxidation or powder coating) to form a dense protective layer on the surface. It is then resistant to corrosion from humidity, salt spray, acids, and alkalis.

Aluminum's rigid strength and lightweight characteristics (only 1/3 the density of steel) make it structurally stable and resistant to bending and deformation in strong winds (up to 140km/h wind resistance) or snow (0.5kN/m² snow load resistance). This avoids the risk of tearing the membrane due to frame deformation.

Choosing high-quality materials is a long-term investment that pays off. Poor-quality metal is prone to corrosion and deterioration, and frequent maintenance or replacement will push up the cost significantly. A high-quality aluminum frame with a UV-resistant PVC cover will last 20 years in harsh weather.

Strong Anchoring System for Various Terrains

Based on the high strength and weather resistance of the material, it becomes a challenge to secure the building firmly in variable terrain to ensure overall safety. That's why you need to consider whether it has an anchoring system adapted to various terrains.

Our Sheltent clear span tents are designed with anchoring kits for flexibility in adapting to a wide range of ground conditions:

• Steel Stake Anchoring (grass/soft soil): High-strength steel stakes are deeply embedded in the ground, suitable for temporary event venues (e.g. music festivals, camping areas), easy to install and cause minimal damage to the ground surface.

• Expansion Bolt Anchoring (concrete/hardened floor): The use of rust-proof alloy expansion bolts, pre-drilled and locked, improves the tensile strength of permanent or semi-permanent tent buildings (e.g. storage centers, workshops).

• Tent ballasting system (non-destructible ground scenes): It can choose the cement pier or use a load-bearing frame for weight.

However, cement piers are not convenient for transportation, so the form of load-bearing frame is mostly used. Applicable to parking lots, ecological protection zones, and other areas that need to protect the ground.

Structure Reports Available

A structural report verifies the design rationality and load safety of the tension fabric building. Third-party certified reports (e.g., SGS, TUV) are indispensable. Sheltent has not only the certificates but also the corresponding test reports (SGS, National Standard Certificate, IFAI, ISO9001, TUV, etc.).

Besides, we carry out simulation tests and field verification in accordance with the building codes of the project site.

High Customization

Different scenarios have different requirements for functionality, design, and scalability, and only highly flexible customized solutions can accurately match the actual usage.

Sheltent supports customizable services, from functional modules to aesthetic designs that can be adjusted on demand.

Common Tension Fabric Building for Different Needs

After clarifying the key considerations for purchasing a tension fabric building, the next step is to select the specific product that suits your needs.

Sheltent's extensive product and high degree of customization can cover a wide range of scenarios, from temporary events to long-term operations. Here are two classic products:

A-frame Clear Span Tent

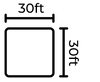

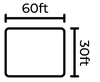

Our A-frame clear span tent is made with a sturdy aluminum frame (6061-T6) and galvanized steel (Q235) components. It can withstand wind loads of up to 120 km/h and protect against inclement weather. Its PVC fabric is coated for effective flame retardancy. It is flame-retardant to class B1 according to DIN 4102-1 for high safety.

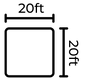

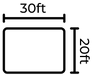

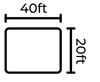

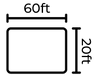

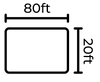

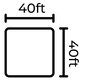

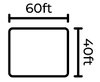

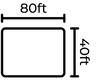

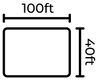

Our A-frame clear span tent is available in widths up to 80 meters and any length. This allows you to customize a tent large enough to accommodate guests or goods.

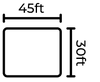

Two Story Tent

The two-story tent is an innovative structural tent that cleverly combines two separate tents into one, expanding the available space. Its frame is made of 6061-T6 aluminum alloy and the first floor is supported with interior poles, which enhance structural stability.

This frame structure improves the overall strength and stiffness and also enhances the load-bearing capacity of the second floor. Its upper floors, on the other hand, are spacious without intermediate columns. It is highly preferred for brand presentations, business meetings, sporting events, and other events.

Conclusion

Tension fabric building offers flexible and efficient solutions for a variety of application scenarios. By carefully considering the multiple factors mentioned above, you can choose the one that meets your specific needs.

If you wish to learn more about how to customize tension fabric structures for your scenario, our professional team will provide you with full-process support from technical consultation to on-the-ground implementation. Contact us today for your customized solution!

FAQs About Tension Fabric Structures

How Long Do Tension Fabric Buildings Last?

It depends on the quality of the material, the environmental conditions and the level of maintenance. Aluminum frames have a life expectancy of 20 years in conventional environments; PVC has a life expectancy of 5 years, which can be realized by regular cleaning and repair of damage; and galvanized steel components have a life expectancy of 10 years.

How Much Does a Tension Fabric Building Cost?

Tension fabric buildings typically cost between $10 and $15 per square foot and increase as the building becomes more complex. Factors used to calculate tension fabric building costs include building size, design, material and customization.