How Much Does It Cost to Build a Warehouse? (2025)

As your business continues to expand, you might need to construct more warehouses to meet the growing demand of streamlining the distribution and delivery processes. This is the inevitable path to the growth of your company. And surely, you are gonna "pay" for it.

So it's only normal for you to ask: how much does a warehouse cost?

Generally, the warehouse cost per square foot is $30 to $200. And the overall size of such a building ranges from 1000 - 1000000 sq ft. For the total expense, it is suggested that you prepare at least $100,000 to $65,000,000 for this structure.

However, the costs to build a warehouse are not fixed. There are several factors that may have a great influence on the overall expense, including the structure size, construction methods, materials, design complexity, etc.

Here in this article, we are going to explain what factors may affect the warehouse cost and discuss whether you should buy or rent one. If you are going to build a warehouse, you should never miss all the information and tips in this blog.

What Mainly Affects the Cost to Build a Warehouse?

The average price of the warehouse may be affected by many factors. Any additional service or requirement would increase the cost to build it. But basically, it is mainly influenced by the 5 major aspects listed as follows:

Purpose of Use

The intended use of the warehouse is one of the key factors to determine its cost. You would invest more if you are going to use this building for manufacturing or distribution than simply construct a storage tent to store goods or other items.

Size of the Warehouse

The size of the warehouse also has a great influence on the cost of building it. It goes without saying that a small warehouse requires fewer materials and labor than a larger one. Then it would naturally generate fewer costs. Therefore, it's important to adjust your budget according to the expected size of your warehouse.

Types of Materials

Simple truth: the materials are better, the quality is higher. And this would influence the eventual pricing of a warehouse. Reliable manufacturers would use high-premium materials like aluminum alloy, concrete, glass, and insulated metal panels when building a warehouse. And you may need to pay more for their durability and excellent performance in long-term use.

Warehouse Construction Methods

The methods of construction can be different, and the cost may vary. The common warehouse building systems include pre-engineered aluminum alloy construction, tilt-up construction, and structural steel-frame construction. Each method involves different materials and techniques, so as to generate various price points.

Warehouse Design

The design of your warehouse is a key factor in deciding the final price, too. It may be constructed with different roof styles and layouts. The complex design often requires more labor, materials, professional services, and additional engineering time. All these would increase the overall expenditure of a warehouse.

Other Factors to Warehouse Construction Cost

Apart from the major aspects, there are other potential factors that may determine the warehouse construction cost. They may include:

-

Foundation conditions: Poor soil quality or unstable ground may require extra reinforcement, thus increasing expenses.

-

Additional accessories: Insulation, doors, climate control systems, and other customized accessories are all vital for offering better protection, while at the same time, they generate more costs.

-

Expansion requirements: If you want to expand the warehouse anytime in the future, then you might need to pay more for this flexibility.

-

Permissions: Local laws, building codes, or environmental regulations may delay projects and incur compliance fees.

-

Labor and time: If the warehouse is made by skilled laborers or with tight deadlines, it can definitely escalate wages, and finally influence the price.

All these factors mentioned above could help determine the eventual overall cost of your warehouse. Thus, to make a more accurate budget plan, it's better to evaluate them all and consult your manufacturers or experts if necessary.

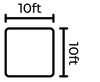

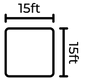

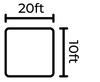

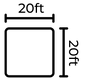

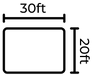

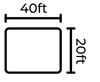

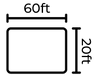

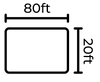

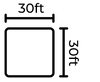

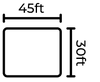

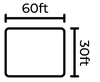

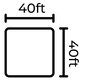

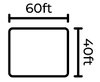

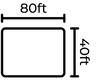

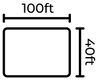

Warehouse Prices by Size

Among all the factors, the size of your warehouse is the most important one to determine the overall expenditure. The general expense of small warehouses of 5,000-10,000 square feet is around $350,000 to $800,000, and for large ones, say, a 50,000 square foot warehouse, the cost would be about $1,250,000 to $2,250,000.

For better understanding, we will use a clear table to list warehouses in multiple sizes and the total costs of each. Before you decide to build one, compare the prices and find the one that suits you the most.

The total cost of a small warehouse is less than a larger one. However, due to economies of scale, the larger warehouse costs less per square foot. Therefore, from a long-term perspective, if the budget allows, it's advisable to choose a slightly larger warehouse.

How to Limit the Warehouse Prices?

Though owning a warehouse can cost you a lot of money, there are still some tips for you to cut down on the overall expenses. You may try the following handy tricks:

-

Use natural light: It is vital to add skylights or big windows to the sides. This can help make the most of the light from nature, so as to cut electricity bills.

-

Control temperature: You should keep the warehouse at the right temperature. This protects goods from damage and extends the lifespan of the warehouse, so as to further lower any repair costs.

-

Reduce humidity: The damp air will ruin cardboard boxes, mold fabrics, and rust metal parts. Keep humidity at 40-50% to protect your inventory from these expensive losses.

-

Bypass middlemen: A good way to limit warehouse prices is to directly contact a reliable supplier. This way, you'll save lots of markup fees and commissions of intermediaries.

-

Use space wisely: It's recommended to optimize the layout by using vertical storage. That is, stacking things higher with tall shelves. It can increase capacity without expanding the building.

-

Automate inventory management: Making the entire warehousing system smarter is also crucial. Thus, try to implement RFID or barcode systems to reduce labor costs and minimize errors.

What About Renting a Warehouse? How Much to Rent a Warehouse?

According to the market price rating nowadays, buying warehouses would cost you at least $100,000 (a small one of 1,000 sq ft). That can be considerably expensive for someone whose budget is tight. But how about renting one? How much is a warehouse in this way?

This may depend on the size, the rental rate, and estimated operating costs. Take the warehouse of 5,000 square feet as an example: suppose that you use it for storage and pay the rental fees monthly. Then the major costs include two parts: $0.85 per square foot for the average base rental rate and $0.25 per square foot for the estimated operating expenses.

In total, choosing such a small warehouse for rental would cost you $5,500 per month. But the actual fees may only be higher because you have to take other operating costs like electricity and water use into account.

Rent or Buy a Warehouse?

It is hard to choose between renting and buying a warehouse. Both have their advantages. But you can make the decision by comparing their costs, intended uses, and duration.

Buying a warehouse may require more initial costs, but it could save you lots of money in the long run, as you don't need to pay the rental fees every month or year. In contrast, renting a warehouse is a better choice if it is a short-term investment because you only need to pay the rental fees for several months. The total cost is way cheaper than directly purchasing a warehouse.

The intended uses of the warehouse can also determine whether to buy or rent it. If you only use it for temporary storage, then renting a warehouse is more recommended. However, if your business is expanding, and you want to build it for logistics and even set up an office area in it, just buy a warehouse!

Some Tips for Warehouse Construction

Except for cutting down the overall warehouse cost, there are also some pro tips for your warehouse construction:

-

Nail Down the Specific Size of Warehouse

To determine the warehouse size, you may start by measuring your stock volume and growth projections for 3-5 years. And it's necessary to allocate 20-30% extra space for aisles, loading docks, and other essential equipment when you are estimating the size.

More importantly, opt for taller ceilings (e.g., 30+ feet), as this may help you maximize vertical storage.

-

Ensure You've Obeyed Relevant Laws & Regulations

Then you have to comply with relevant building codes. You might need to ensure the land is approved for industrial use by consulting the local government. Additionally, meeting safety standards is also important. You should include fire exits, sprinklers, and earthquake-proofing (if applicable).

-

Select a Reliable Warehouse Manufacturer

Last but not least, partnering with a renowned warehouse manufacturer is of great significance. It can not only build top-quality warehouses for you, but also give you professional suggestions on running your warehouse in the long run. They've got the expert team to assess the feasibility of the project before construction begins and make timely adjustments for optimal results.

Build Your Warehouse with a Reliable Manufacturer - Sheltent

Building a warehouse can be a pretty easy thing if you have chosen the right manufacturer. It will calculate the accurate cost to build a warehouse and ensure the high performance of the structure in the long run. Therefore, when building your warehouse, it is advisable to prioritize a trustworthy supplier like Sheltent.

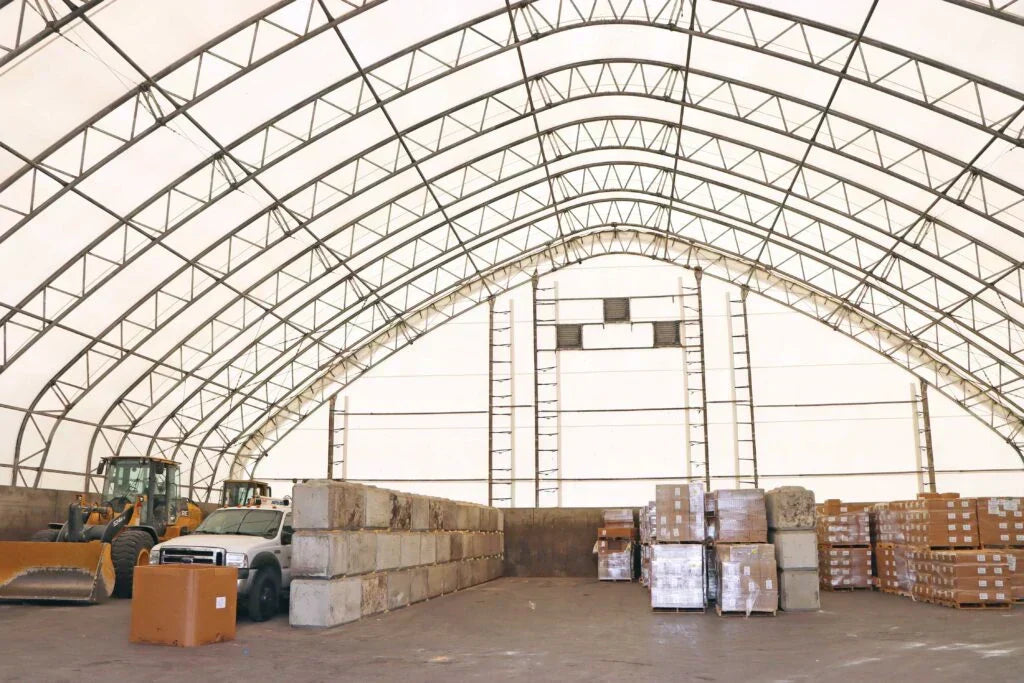

Our clear span tents are composed of a prefabricated aluminum alloy frame. Due to this brilliant design, they can be quickly set up. The aluminum alloy is light yet very sturdy, so they are also easy to transport and strong enough to withstand any harsh weather conditions.

The A-frame clear span tents and arcum tents are the most common ones used to build warehouses. They have been widely used for storage and various large outdoor events.

Besides, all of our tents are able to be used for a very long time. If maintained well, their lifespan can be extended to nearly 15 years. You can also easily expand it or customize additional accessories based on your specific needs and requirements.

At Sheltent, we would try our best to serve every guest. You can find almost all kinds of warehouses for sale on the market, ranging from arcum clear span tents to flat roof clear span tents. When cooperating with us, you don't have to worry about any part of building your warehouse. We have worked in the tent area for nearly 10 years. Thus, we are very confident that we can meet all your demands.

So, just bring it on if you have any questions about your warehouse, no matter its cost or any other important aspect you want to know more about.