What Is a Tent Structure?

As a flexible and modern spatial solution, the tent structure is quietly penetrating into various scenarios of daily life, from spectator stands for sports events to creative exhibition areas for corporate events. This seemingly simple structure can be quickly erected to cope with emergencies and can also be professionally designed to become semi-permanent tent structures.

However, in the face of material, load-bearing, environmental adaptability, and other factors, how do you choose the most suitable tent structure for specific scenes? This article will reveal the answer.

🎈 You May Also Like: 10 Questions to Ask When Buying Fabric Buildings

What Is a Tent Structure?

A tent structure is a combination of the frame and exterior covering material used to support the tent. It usually consists of components such as a support frame, a tarp, and connectors. The support frame can be metal, wood, or other sturdy material, and the tarp is a waterproof, durable fabric. The design of the tent structure determines its stability, durability, and the environmental conditions to which it is applied.

Key Features & Benefits of Tent Structure

The advantages of the tent structure come from the precise matching of its design logic and practical needs, which are reflected in the following aspects:

• Prefabricated Modular Design

"Prefabricated" refers to components that are manufactured in advance at the factory and delivered ready for on-site assembly. This structure uses standardized parts, such as aluminum profile frames, pre-cut tarpaulin, and plug-in connectors - allowing for fast setup without the need for professional construction teams.

The modular tent system also supports flexible expansion and reconfiguration, making it ideal for exhibitions, warehousing, and other scenarios that require frequent installation and relocation.

• Cost-Controllable, Economical, and Efficient

The structure uses mainly lightweight aluminum alloy, which reduces both material and transportation costs. Its prefabricated and reusable design significantly lowers initial construction expenses—typically 30% to 50% less than those of traditional buildings. Because no complex foundation or heavy equipment is required for installation, labor costs are also minimized.

In the long run, maintenance is simple and inexpensive, involving only periodic checks of the tarpaulin surface and frame connections, leading to even greater cost-efficiency over time.

• Strong Weather Resistance, Adaptable to Multiple Environments

The tarpaulin typically features a double-layer structure with surface PVC coating treatment, offering excellent waterproofing, flame retardancy, and UV resistance. It performs reliably in a wide temperature range from -30℃ to 70℃.

The overall structure is engineered with a combination of tensioned design and stable frame support, providing strong resistance to wind, snow, and other environmental loads.

• Stable Structure, Safe and Reliable

The frame is made of high-strength materials (such as aluminum alloy or steel ), and the nodes are mechanically optimized to ensure stability.

Types of Tent Structures

Tent structures have evolved into various types due to differences in application scenarios and technical principles. The frame-supported type is mainly made of metal tubes, the air-supported type relies on air pressure to maintain its shape, and the tensile membrane structure is molded by the tension of steel cables.

Different types have their own focus in terms of setup efficiency, space span, and environmental adaptability to meet diversified needs.

Frame-supported structure

The frame support structure tent takes the metal pipe or profile as the load-bearing frame, and the main body is constructed of aluminum alloy or galvanized steel material. The aluminum alloy frame is designed for quick disassembly and assembly through lightweight design, which is commonly used in temporary scenarios such as exhibitions, outdoor activities, and so on.

Additionally, by using heavy-duty aluminum profiles with secure anchoring systems, these structures can also serve as semi-permanent installations suitable for long-term use.

The steel frames, often reinforced with thicker pipe walls and treated with hot-dip galvanizing, offer enhanced strength and durability. This makes them particularly well-suited for large-span, heavy-duty applications such as warehousing, logistics hubs, and industrial shelters. Both types can be flexibly combined with modularized design.

Air-supported Structure

Tents with air-support structures rely on air pressure to maintain shape and stability. Continuously inflated by a built-in fan, the tent's outer membrane is expanded and supported. Lightweight, quick to erect, and without the supporting elements of a traditional frame, this type of structure is suitable for temporary events or venues where large spaces are required.

Air-supported structures usually have good wind protection and are suitable for environments where structural stability is important.

Tensioned Membrane Structure

A tensioned membrane structure forms a self-balancing system through the synergistic action of tension between high-strength flexible membrane materials (such as PVC, PTFE, ETFE) and steel cables or a skeleton. Its membrane self-weight is extremely low, and with tension distribution, it can achieve more than 200 meters of column-free space, significantly reducing the material consumption and construction cycle.

PTFE/ETFE membrane material has both 10%-20% natural light transmittance and UV-resistant coating, which is both light and energy-saving and self-cleaning; the ETFE air pillow structure further optimizes the energy efficiency through the double-layer thermal insulation design. It is widely used in large-span public buildings, commercial facilities, and temporary spaces.

Wide Application of Tent Structures

Tent structures have a wide range of applications in different scenarios, and the following are their main uses:

• Temporary Applications: exhibition activity tents, emergency rescue shelters, outdoor exhibition halls, and commercial promotional booths to meet short-term, high-frequency dismantling and installation needs.

• Semi-Permanent Applications: industrial warehousing tents, temporary expansion of stadiums, and logistics transit stations, designed for a life of 20 years, taking into account the economy and functionality.

• Permanent Applications: gas membrane stadiums, membrane structure transportation hubs, and landscape architecture through high-strength materials and intelligent systems to achieve long-term stable operation.

What's the Difference Between Temporary Tent Structures and Permanent Tent Structures?

Once you know what temporary structures are and the application scenarios for permanent buildings, do you know the difference between them?

All in all, the most obvious difference between temporary and permanent tent structures is their purpose. Next, we will compare these two types of tent structures in detail from several aspects.

Budget

Temporary tent structures are suitable for short-term projects with limited budgets due to the use of standardized prefabricated modular components and simple installation methods, resulting in lower initial procurement and erection costs. However, its frequent dismantling and installation will lead to the accumulation of labor costs and accelerated membrane wear and tear, which may offset the initial price advantage in the long term with multiple uses.

Although the initial investment for a permanent tent structure is relatively high, due to factors like customized design, high-specification membranes, and steel framing, it offers greater cost-efficiency over time.

With a service life of up to 20 years or more and reduced maintenance needs (for example, PVC with self-cleaning coatings lowers cleaning costs), it is especially suitable for functional spaces that require continuous operation.

Customization

The need for customization is even more pronounced for permanent tents, which have to cope with complex application scenarios. During the design stage, the following factors require particular attention:

• Site Foundation Conditions: Ground type, soil bearing capacity, and terrain differences will impact the structural base design.

• Structural Load Requirements: Permanent tents often need to withstand long-term static and dynamic loads, including wind, snow, and equipment weights.

• Stability and Safety Standards: Ensuring long-term structural integrity calls for precise calculations and professional verification.

• Compliance with Local Regulations: Fire safety, wind resistance, and seismic standards must be fully considered and met.

These challenges typically require structural engineers and architects to work closely together to develop a tailored and optimized solution.

In contrast, temporary tents are mainly standardized units, with customization options primarily focused on optional accessories, color schemes, and basic structural configurations. The scope for customization is generally limited to size adjustments and the branding logo.

Stability

Permanent tents are more stable than temporary tents. As mentioned, these tents perform better than the temporary ones, even in the same weather, because they're made of different materials with different foundations.

For example, at the same wind speed, the permanent tent will perform more stably due to its stronger structure and higher wind resistance. Temporary tents, however, although designed with stability in mind, are less stable and may require additional reinforcement due to the use of lighter materials and mobility.

Foundation

Temporary tents often use stakes or expansion bolts as base fixing, making them simple to erect and easy to dismantle. Permanent tents, on the other hand, tend to use embedded bolts or a separate base fixing solution supplied by the professional manufacturer, which is a much more secure way of fixing.

Common Temporary and Permanent Structure Tents

The selection of a tent requires a comprehensive consideration of the scenario, cost, and expected service life. If you are preparing for an event show or planning a long-term space solution, Sheltent can provide customized solutions from rapid deployment to industrial reinforcement to match your different scenarios. Here are a few popular tents.

Pole Tent

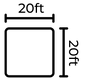

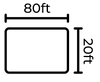

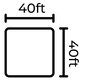

With its simple structure and prefabricated modular components, the pole tent is ideal for temporary events. It is easy to transport and set up. Its modular construction also makes it easy to combine multiple standard-sized tents to form a variety of sizes and shapes.

And it is supported by center and side poles, which are fixed to the ground by an anchoring system that generates tension to keep the top of the tent tension, ensuring the stability of the tent.

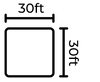

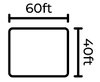

Frame Tent

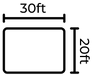

The frame tent is also a great tent structure for temporary setups. Unlike pole tents, frame tents are supported by a separate metal frame, eliminating the need for a center pole, making the interior more spacious and flexible for events that require maximum use of space.

For example, you can display your merchandise at will during some merchandise promotions or new store opening discounts.

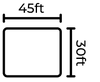

A-frame Tent

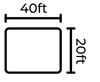

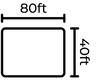

A-frame tents are ideal for long-term use due to their sturdy construction and high durability. The frame, usually made of aluminum alloy profile, is highly resistant to wind and pressure and can withstand extreme weather conditions such as strong winds, heavy rain, or snow without being easily deformed or damaged.

Moreover, the PVC of the tent makes it waterproof, UV resistant, and durable, reducing maintenance frequency and cost. Therefore, it can provide you with long-term, stable performance.

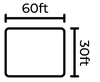

Polygon Tent

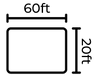

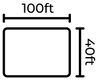

The polygon tent features a distinctive hexagonal structure that offers both visual uniqueness and practical stability. Its geometric form distributes structural stress more evenly, enhancing wind resistance and overall durability.

Built with a robust aluminum alloy frame, the tent maintains reliable performance in challenging outdoor conditions, including wind speeds of up to 120 km/h. With a life expectancy of typically up to 20 years and minimal maintenance, it is a reliable, economical choice for long-term applications.

Conclusion

When choosing a tent structure, it is necessary to consider various factors such as application scenarios, cost budget and service life. Different types of tent structures (e.g. frame-supported, air-bearing and tensile membrane structures) have their own characteristics and are suitable for different demand scenarios.

Temporary tent structures are suitable for short-term activities due to their low cost and quick setup, while permanent tent structures focus on stability, durability and customized design for long-term functional space.

That’s why it’s worth considering choosing a partner who can offer the right structure for each scenario. The Sheltent brand is able to respond flexibly to a wide range of needs, from rapidly deployable temporary tents to industrially reinforced permanent tents, with customized and quality services to ensure that the user receives the best cost-effectiveness and long-term security. Contact us today!